The objective of this proposal consists in a demonstration action aimed at evaluating the applicability of the acoustic underwater technologies developed in the SUNRISE project, integrated in the low-cost acoustic modem, with other devices for the environmental monitoring of an underwater fish farm. Although a complete environmental monitoring system would require financial budgets and development times far behind the ones allowed in this call, a first step in this direction is undertaken in this proposal in that a small sensors network consisting of three underwater nodes located at suitable depths, either within or out the fish farm cages, and one data collecting central station located in a floating buoy on the sea surface will be built up by exploiting the networking and internet access functionalities provided by the Re-Deployable SUNSRISE Testing Facility.

FISH FARMING

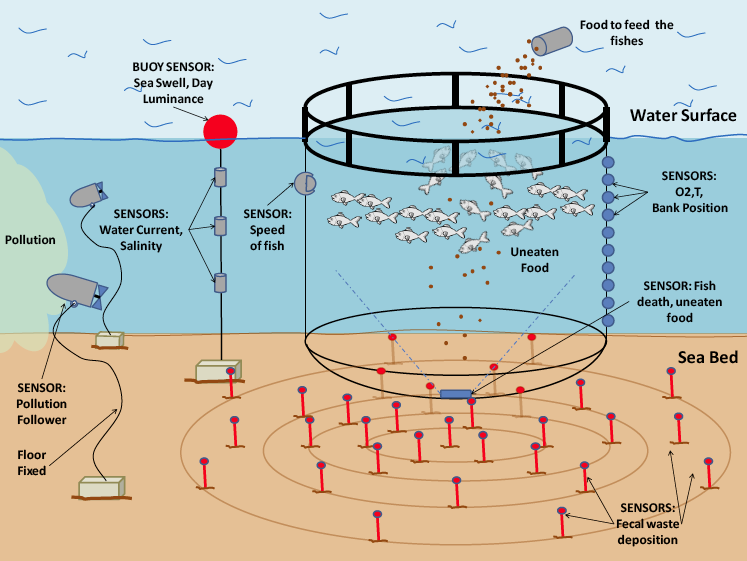

Figure 1: Fish farm

Fish farming is the process of raising fish commercially for food supply in tanks, enclosures or in net pens or cages when located offshore of coastal areas or in freshwater lakes. With the ever increasing global demand for food and widespread overfishing of wild schools of fish, a term used to describe the phenomenon whereby wild fish are captured at a faster rate than they are able to reproduce, it expected that fish farms offer in the future a reliable food supply for millions. In fact, with the world population standing over 7 billion in 2011 and rapidly growing, it is vital to think of global food production capabilities as we will approach 9 billion in 2040. The demand for fish has more than quadrupled from 1950 until today and it is still steadily increasing. Intensive farming may consist of 35-50 Kg of fish per cubic meter whereas in biological farms such amount is around 10-11 kg per cubic meter. This limitation causes less Oxygen stress, resulting in lower fish mortality. Because of the disposal costs required to remove dead fish, in intensive farms they are fortified by drugs (antibiotics) with evident environmental problems caused by not consumed molecules of drugs that remain in the marine environmet and may be ingested by wild fish close to the breeding cages. Underwater fish farming is considered a high-impact aquaculture method due to the waste which passes freely from the fish farm to surrounding waters, the ability of farmed fish to escape and compete or breed with wild fish, and the spread of diseases and parasites to wild fisheries. Thus, making fish farms sustainable requires a careful management and monitoring because their impact on the surrounding can be heavy. In order to be sustainable, fish farms must minimise their impact, by treating wastewater, containing stocks, preventing the spread of diseases and not removing fish, particularly juveniles, from wild fisheries. Of course it should be economically profitable, an issue that is not necessarily in conflict with environment protection. To this regard, one aspect is the efficiency of the feeding process related to the healthy growth of fishes against the cost of the lost food. Reducing wasted food is also important from environmental protection reasons because it is deposited in the seabed and usually generates an environmental impact on the surrounding area. It may cause failure to uphold aquaculture legislation. Another economical aspect is the water quality within and around the farm allowing the maximization of the production of high quality species. This leads to the following issue to be addressed: what is the minimal number of physical and chemical variables to be monitored in order to be sure that the water quality is enough good to ensure the production of the maximum number of fishes with the highest possible weight? Many water parameters are usually measured when the farm is established: pH, salinity, temperature, dissolved Oxygen, the transparency, the suspended solids, ammonium, nitrates, the total nitrogen, among others [1, 2, 3]. This information is used to select the most appropriate place for the cages and the most appropriate environmental measuring system. According to some studies, each species grows best between some specific temperature ranges. Low temperatures will affect the feeding process because the fishes eat less. Oxygen and turbidly are also limiting factors in fish growth. Fishes do not feed well at low Oxygen and high turbidly concentrations. Each species has its optimum Oxygen range.

According to the report published by Transparency Market Research—Aquaculture (Marine Water, Freshwater and Brackish Water) Market for Carp, Molluscs, Crustaceans, Salmon, Trout and Other Fishes – Global Industry Analysis, Size, Share, Growth, Trends and Forecast, 2013 – 2019—the global market for aquaculture was valued at $135.10 billion in 2012 and is expected to reach $195.13 billion in 2019, growing at a CAGR of 5.1% from 2013 to 2019. In terms of volume, global production was 66.5 million tons in 2012 and is expected to grow at a CAGR of 2.3% from 2013 to 2019. Volume of captured fish is fast depleting and is expected to be one of the primary factors driving global aquaculture production over the next few years. In addition, increasing consumer awareness regarding health benefits associated with consumption of fish and fish products is expected to boost aquaculture production within the forecast period. Aquaculture is expected to surpass captured fish industry as the major source for human consumption by the end of 2015. Aquaculture practiced in fresh water was the largest culture environment segment in 2012, accounting for more than 60% of the production. It is expected to be one of the fastest growing segments over the next few years on account of simulation of the culture environment in enclosed areas such as ponds, cages, and concrete raceways. Aquaculture practiced in marine water is expected to grow at a CAGR 2.4% from 2013 to 2019 due to increased consumer demand for sea water fish. Carps were the biggest product segment within the market and accounted for more than 35% of the global production in 2012. Carps, particularly common carps, have been one of the major farmed aquatic species in the industry, owing to their compatibility in less than ideal environmental conditions. Molluscs such as clams and mussels have been an important food source and are expected to witness the fastest growth over the next few years. This segment is expected to grow at a CAGR of 2.6% from 2013 to 2019, owing to their increasingly use in poly culture systems such as rice and fish farming. China dominated aquaculture production and accounted for more than 60% of the total share in 2012. In addition, this region is expected to witness the fastest growth within the forecast period. Cheap labour, ease of availability of natural resources, and induced conditions for aquaculture are some of the key factors that are expected to contribute significantly to the growth of the market in this region over the next few years.

FEEDING PROCESS

The feeding process is nowadays mostly carried out by dropping the food in the cages by using crafts with fixed pipes in each cage impelled by air compressors. The control of the exact moment when the uneaten food begins to fall to the seabed is currently done by Scuba divers or by submersed cameras, which are introduced and removed from the water every time the fish should eat. When the uneaten food starts falling, the divers warn the operators on the sea surface that stop the feeding process to avoid wasting of food. In addition, in the presence of strong currents, the feed could come out of the cage and then will be consumed only in part or even not consumed at all. In this case, the food is not provided for both finantial savings and evironmental protection. This caution leads to large financial savings to the company, especially if biological food is used, and avoid huge accumulation of non-consumed food in the seabed, otherwise leading to asphyxiation of all areas that would be completely submerged by the food. A prudent administration of the food is also paramount for ensuring a normal life cycle of fishes, which defecate according to what, how and how much they eat. These factors can make the farmed fishes produce more waste material (faeces), based on the mixture of these factors. The use of non-controllable feed may lead to a rapid fattening of the fishes. This alters their normal organic cycle and their droppings increase, causing serious problems of alterations of the environmental conditions. Also damages would derive to the cages by the spraying of organic material over them that must be disposed of to avoid plants and animals to populate them. Finally, all the waste that will be able to leave the cages will cause algae overproduction and eutrophication of surrounding environments.

WATER QUALITY REQUIREMENTS

Based on the above considerations, a monitoring system that will be able to detect this increasing of speed, fall of uneaten feed and other specific fish behavioural patterns of interest would be a significant advance in aquaculture, from the standpoint of feeding

Figure 2: complete fish farm sensors network

control, environmental protection and farm sustainability. According to many authors and studies, some of the most important sensors to install within and around a fish cage include:

- Sensors for the cage water column temperature, dissolved Oxygen, and turbidly: The species usually eat more when temperature is higher and grow best between some specific temperature ranges. In addition, fishes do not feed well at low Oxygen concentration. These parameters and the water turbidity are limiting factors in fish growth.

- Sensors for water current and salinity: It is important to define the water current in order to calibrate the measures of speed sensors and to define the uneaten food spread. A very abrupt salinity change may mean the death of many fish. Salinity changes should not be too high.

- Sensors for the fish speed: In most species, the speed of the fish is directly related to their hunger. If the fishes are moving quickly, it is because they are hungry (but it could also be caused by the appearance of a depredator near the cage).

- Sensors that let us know when the feed begins to fall on the seabed and its quantity: One of the main issues to take into account in sustainability in marine fish farms is how faecal pellets and uneaten feeds are spread under the cages. These depositions are settled some distance from the farm implying an adversely impact in the coastal environment.

- Sensors to detect and follow the water pollution of the water column in the cage surroundings: The quality of water is one of the most important parameter related to the fish growth. If water would contain heavy metals, these fish would be unfit for human consumption. The dumping of other substances may cause massive death of fishes inside the cage.

UNDERWATER SENSORS NETWORK AND TELEMETRY

The sensors network aims at monitoring in real-time those physical and chemical variables related to the water quality of the farm and usually include: Ph, Conducibility, Dissolved Oxygen, Water Temperature, Chlorophyll A, Turbidity. In this project, we plan to use two types of multiparametric probes, namely types A and B, connected to the three underwater nodes provided by the SUNSRISE project, one of them equipped with a probe of type A and the other two with probes of type B. The A type probes will be measure: Ph, Conducibility, Dissolved Oxygen, Water Temperature, Chlorophyll A, Turbidity whereas probes B will measure a subset of: Ph, Conducibility, Dissolved Oxygen, Water Temperature. Notice that such a difference will allow us to satisfy the budget available for the project.

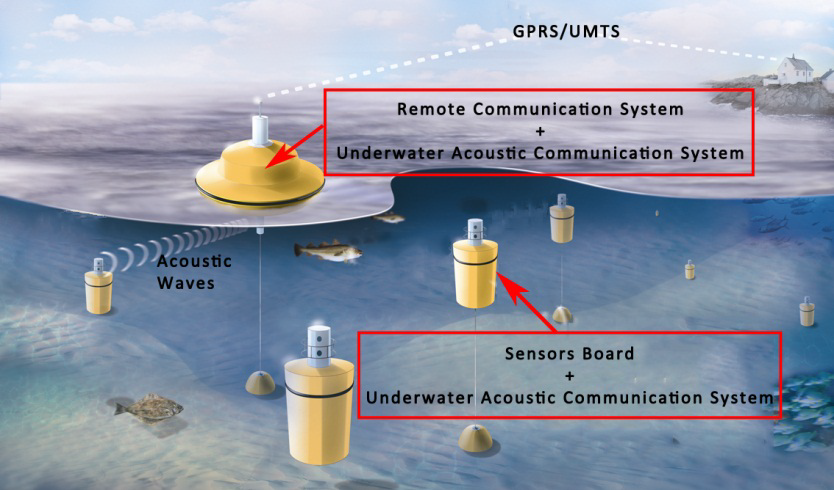

Figure 3: Re-deployable testing facilities

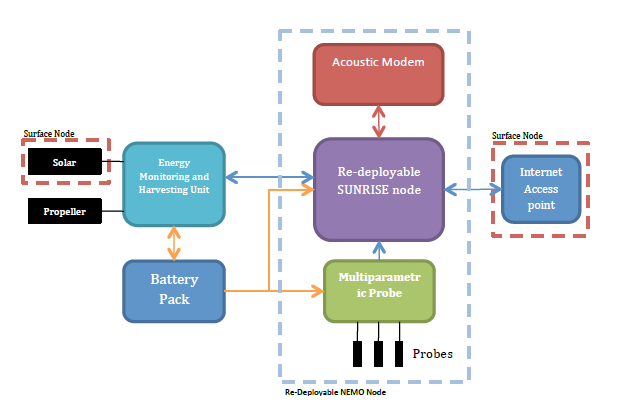

Such variables will be collected by each single underwater node and transmitted via an acoustic link to a data collecting central station on the sea surface three times at a day. The latter will be wirelessly connected to Internet via a 3G/4G modem and will allow sensors network interrogation and the population of web database with the sensed data, augmented by a time-stamp indication. Each underwater node will consist of:

- A underwater acoustic modem able to support SUNSET functionalities;

- A SUNRISE node equipped with SUNSET S-SDCS functionalities and with connections for a modem and a probe;

- One multiparametric probe supported by the SUNSET framework;

- Energy interface and monitoring and underwater harvesting units connected to each node (based either on a propeller or a solar panel);

- Wireless Internet Access Point (only for the surface node);

- Battery pack.

In addition, the SUNRISE database will be configured for storing and processing the data coming from the probes via the SUNRISE GATE interface. These data will be referenced in ime (and space) and used to prepare the water quality reports and any other document of interest.

Figure 4: Node Schematic

The specific application need a low-cost underwater modem with the possibility of its complete customization. Its main features are hereafter reported. Modem have to offer a suitable open hardware/software platform for developing underwater cost-effective control, communication and localization applications, especially in their first concept- validation phases. Fish farms usually are installed in shallow water environments and the used modem have to use a robust modulation scheme for these applications (i.e. FSK or M-FSK). The working frequency should be around 25−50KHz, with selectable data-rates. The application don’t need high data-rates so also low bit rate modem can be used. Also a selectable transmission power levels is useful for that application. The interface used to interact with the modem will be:

- Universal Asynchronous Receiver-Transmitter (UART) interface.

- Ethernet interface.

The modem should be based on open-source Linux development board for the purpose to integrate SUNSET framework and adding additional software functionalities such as signaling protocols and network capabilities. Another most important functionalities needed, for the purpose of NEMO project, is the acoustic modem interoperabilities, in particular its capabilities to use standard underwater communication protocol. As an example, the JANUS underwater signaling protocol, which is reputed to become a standard protocol for underwater data exchanges, must be supported. The combination of the communication and networking capabilities provided by the modem and SUNSET makes it possible the creation of a compact and complete solution for the creation of an underwater network of devices that can exchange information and cooperate to accomplish more challenging tasks in an efficient, flexible, fast and cost-effective ways.

Energy Monitoring and Harvesting Unit

In order to monitor the energy available on each underwater and surface node, a dedicated electronic unit will be designed in charge to manage the energy harvesting process, from either marine currents energy harvested via propellers for underwater nodes or solar energy harvested by solar panel for the surface node. The board will regulate in a proper way the charge of the battery pack with the harvested power, will be connected directly to one out the four SUNRISE nodes and will allow the following operations:

- Reading of the battery voltage

- Estimation of the battery State-Of-Charge (SOC) by opportune algorithms and models

- Making the current SOC level of the node aware on the Internet and storable into the web server via SUNSET

- Charge in a proper way the battery under energy harvesting.

In order to properly design the energy harvesting device, first of all the propeller and turbine geometry most suitable for the particular sea conditions around the fish farm will be investigated. Two possible solutions could be adopted: the first use a standard propeller and brushless motor as in standard wind turbines whereas the second uses a helical turbine (like the Gorlov or Darrieus designs), that are both examples of vertical axial turbines. One of the main advantages of vertical-axial turbines is that the flow remains perpendicular to the axis, regardless of the flow direction, and the turbines always rotate in the same direction. The main issue that need to be resolved is the turbine position inside the water column. In fact, it is well know that the current velocity varies substantially with the depth and during the day. Multiple turbines could be used to intercept the current available at different depths or a single turbine could be moved up and down along a fixed cable. These solutions will be investigated evaluating the benefit-cost ratio. In the above scenario, the electronic control system of the energy harvesting device has a very important role to increase the efficiency and effectiveness of the node. Also an embedded electronic system for that energy-harvesting prototype will be designed. For the purpose of energy harvesting of the surface node, a solar panel will be installed on the floating buoy.

Surface Data Collecting Central Node

The surface data collecting node of the sensors network will be in charge to initiate, either from an Internet interrogation request or on the basis of a periodically scheduled sensing policy, the data exchange with one or all the underwater nodes. These data will be further elaborated in the central station if required, basically accomplishing some filtering action on them, and then transmitted via the Internet link to the station who requested the data or to the database. This node will consist of a floating buoy with integrated a 3G/4G modem, an acoustic modem that communicates with the underwater nodes of the network, a wireless interface (WiFi and/or ZigBee) to eventually exchange sensors data and other information with a computer closely located (e.g. in a supply or supporting boat) and a power unit whit the battery pack and a small solar panel to recharge it.

DEMONSTRATION VENUE – FISH FARM

The demonstration will be carried out at in an Italian fish farm to be suitably determined, possibly located in the Calabrian region in order to maintain reasonably low the distances between the farm and the University of Calabria. The selected fish farm company will be involved in the project as a subcontractor for the sensors network specifications, final results assessment and data analisys, and for supporting the project in all sea operations.